Color Separation

Color Separation is the process of converting an image, such as photograph, into a set of colors that can be printed.

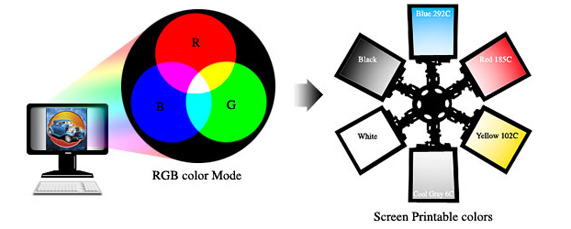

When an image is brought into ®Adobe Photoshop, it is usually in a color mode compatible with the device that it was created on. This is often the RGB color mode, which is a common mode for digital cameras and computer monitors. The RGB mode is based on the blending of Red, Green and Blue light. To screen print an image, the colors must be converted to a combination of colors compatible with screen printing. The resulting set of colors is called a Color Separation.

Customized Color Separations

A color separation may use combination of these three separation styles, depending on the press and design requirements. For instance, a process color separation will often benefit from the addition of a spot color to increase the color range.

A simulated process print may also include a process color or a custom spot color as needed. In practice, customized color separations are often used due to different printer/design requirements.

The act of decomposing a color graphic or photo into single-color layers. For example, to print full-color photos with an offset printingpress, one must first separate the photo into the four basic ink colors: cyan, magenta, yellow, and black (CMYK). Each single-color layer is then printed separately, one on top of the other, to give the impression of infinite colors.

This type of color separation, mixing three or four colors to produce an infinite variety of colors, is called process color separation.Another type of color separation, called spot color separation, is used to separate colors that are not to be mixed. In this case, each spot color is represented by its own ink, which is specially mixed. Spot colors are effective for highlighting text but they cannot be used to reproduce full-color images.

Traditionally, process color separation has been performed photographically with different colored filters. However, many modern desktop publishing systems are now capable of producing color separations for graphics stored electronically. This capability is essential if you want to create full-color documents on your computer and then print them using an offset printer. You don't need to perform color separation if you are printing directly to a color printer because in this case the printer itself performs the color separation internally.

What is CMYK?

CMYK is an acronym for Cyan, Magenta, Yellow & Key (black). CMYK can also be referred to as process color, full color or four color printing. Using different combinations of CMYK, this color model can produce a full range of colors which gives both digital and offset printers the power to reproduce both colored text and images with astonishing results.When an image is printed, it is really a collection of tiny dots of colors that make up the colors of the image. This is similar to how digital images are displayed in pixels. If an image on the web has a low PPI (Pixels per Inch) it will become grainy if you try to make it too large.

How Does CMYK work?

CMYK is a subtractive color model meaning that color is added to a white background to subtract the amount of white space. Cyan, Magenta, Yellow and Black inks are applied to a sheet of paper (or other medium) to make up an image out of all the possible color combinations. An image is separated into dots, which are tiny color selections to make up an image. The amount of dots per inch make up the resolution of the image, and having a dpi of 300 or more will print a vibrant image with smooth and clear lines.

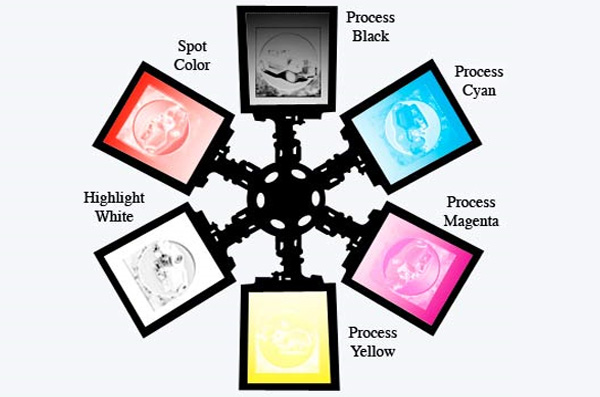

The image to the right demonstrates how an image is split into four color plates using the CMYK colors to make up the full color image on the top.

Separating the Colors

The set of images to the right is a visual description of the separation of colors in an image. The process is actually separating an image into dots for each color (Cyan, Magenta, Yellow, Black). This setup mimics a smooth, continuous color tone to the human eye, instead of being pixilated or blotchy. These dots are measured in Dots Per Inch (DPI), which measures the resolution of an image.

If you look even closer, you would notice that each dot is not 100% solid color; it is actually a transparency and is overlaid by the next color in the sequence (CMYK) to form a new color. This explains how to build a a color in CMYK format. You select a percent of each CMYK to make a blend of the actual color that you want. For example, the image below contains CMYK values of (71, 18, 47, 16) respectively to make up this unique shade of blue.

Digital Printing

Digital Printing refers to methods of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates. It also allows for on-demand printing, short turnaround time, and even a modification of the image (variable data) used for each impression.

The savings in labor and the ever-increasing capability of digital presses means that digital printing is reaching the point where it can match or supersede offset printing technology's ability to produce larger print runs of several thousand sheets at a low price.